Building the Next Industrial Workforce: Why Diversification, Partnerships, and Upskilling Matter

U.S. manufacturing is at a turning point. The future of production, innovation, and economic strength won’t just be powered by machines – it will be powered by people. But the truth is, those people are getting harder to find.

There’s a growing disconnect between the roles manufacturers need to fill and the skills available in the labor pool. That’s why workforce diversification, mentorship, and apprenticeship programs are more than just good ideas – they’re essential. Investing in talent today doesn’t just solve immediate shortages; it future proofs your workforce and opens doors to untapped talent.

The Manufacturing Skills Gap Is Growing – And So Is the Risk

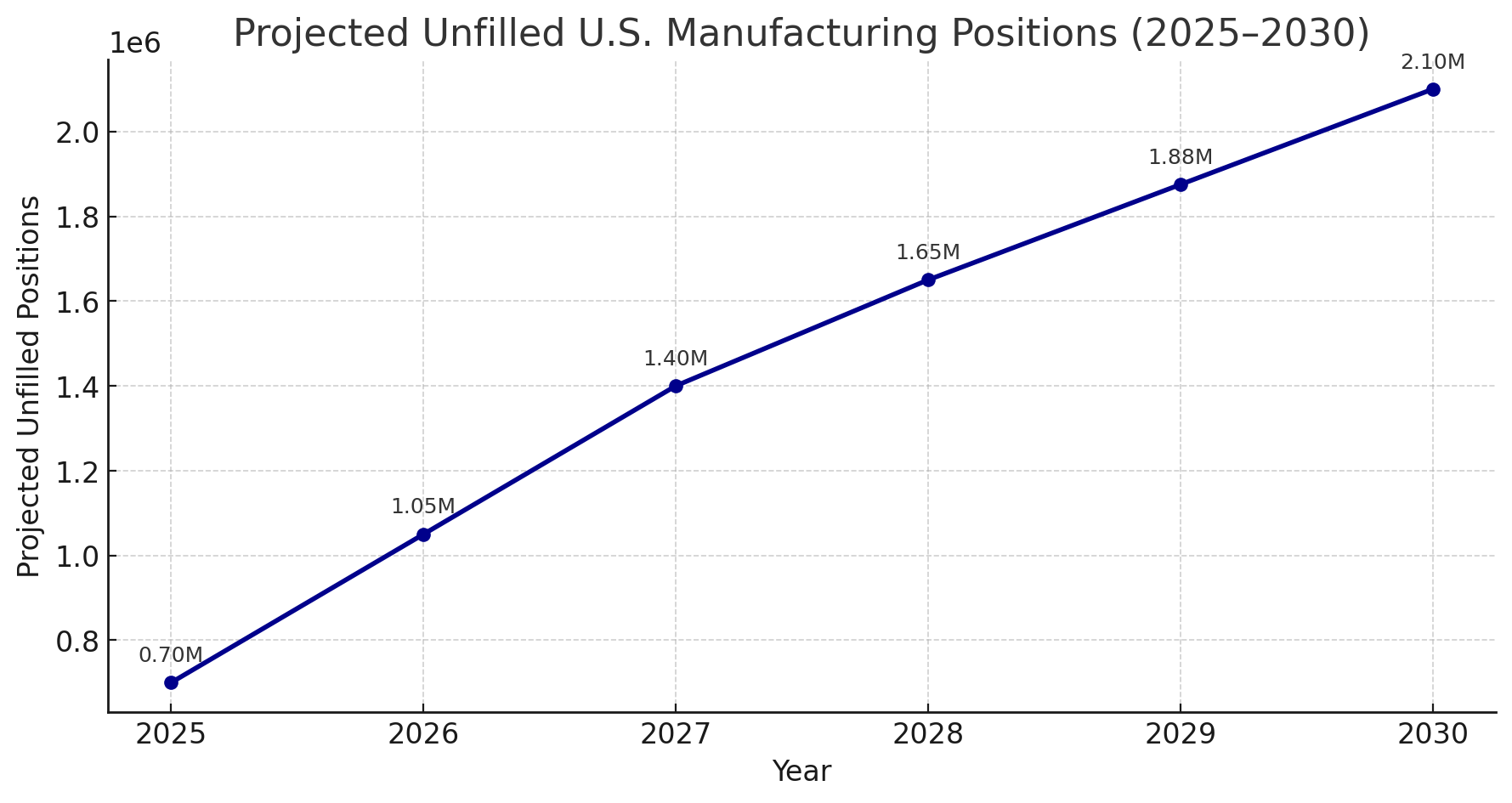

According to the National Association of Manufacturers, more than 2.1 million manufacturing jobs could go unfilled by 2030. Deloitte and The Manufacturing Institute warn that this skills gap could cost the U.S. economy up to $1 trillion by the end of the decade.

*the numbers in the graph are based on projections

Why is This Happening? Several Factors Are at Play:

- An aging workforce – Over 25% of manufacturing workers are 55 or older

- Changing technology – Automation, data analytics, and AI are rewriting job requirements.

- Location mismatch – Many new plants are in rural or economically distressed areas with limited talent pipelines.

- Underinvestment in frontline workers – The general laborers who keep production running are often overlooked.

The old model of relying only on local, “ready-made” skilled workers no longer works. Manufacturers need to rethink both who they hire and how they build talent.

- Recruit new communities – Women, veterans, immigrants, second-chance hires, and non-degree talent.

- Expand geographic reach – Hire regionally or nationally, offering relocation, housing, or transportation.

- Offer flexible schedules – Attract younger workers and caregivers.

Equally important is diversifying workforce development. Strategic partnerships with staffing agencies, trade schools, and community colleges can create scalable talent pipelines – reducing hiring timelines and helping fill even the most difficult-to-staff roles.

A standout example is Mini Manufacturing World, a program hosted by local Wisconsin manufacturers and Madison Area Technical College to introduce high school students to the world of manufacturing. Kallie Schultz, Portage Campus Operations Manager, from MATC, shared how this partnership has made a lasting impression on the students she works with:

“I think the biggest surprise for students is how many different types of jobs exist in manufacturing and how many ways there are to grow within a company.”

This kind of exposure not only opens students’ eyes to career possibilities but also helps build a more informed and inspired future workforce.

Some quick stats:

Mentorship and Apprenticeships: Your Secret Weapon

Mentorship programs let experienced workers nearing retirement pass on their knowledge, speeding up training and boosting retention. For example, one aerospace manufacturer cut training time by 34% and improved retention by 22% through structured mentoring. MATC’s Portage Campus Operations Manager, Kallie, emphasized how mentorship can deepen students’ understanding of career pathways – not just by teaching technical skills, but by humanizing the journey. When students connect with mentors across different departments within manufacturing, they begin to see the real stories behind job titles. These conversations reveal the winding paths, personal growth, and unexpected opportunities that shape careers.

“When students meet mentors from different departments and hear how they’ve grown into their roles, it helps them see career paths they might not have considered before.”

This kind of insight is invaluable. It helps students envision themselves in roles they might never have imagined, and it builds a sense of possibility that can fuel long-term engagement in the industry. Registered apprenticeships are another game-changer. They provide role-specific, earn-while- you-learn pathways built with technical colleges, workforce boards, or trade associations. The U.S. Department of Labor reports 94% of apprentices stay employed after completion, earning an average starting wage of $77,000 in advanced manufacturing.

Why Upskilling Laborers Is a Competitive Advantage – Not a Cost

Frontline workers are the foundation of tomorrow’s skilled workforce. Investing in upskilling helps manufacturers:

- Reduce reliance on external hires for skilled roles.

- Improve retention through clear career paths and higher wages.

- Increase operational agility with internal role mobility.

Companies that invest in upskilling are 20% more productive and 27% more engaged

In today’s manufacturing industry, success depends on more than just filling positions – it’s about helping employees grow. Upskilling not only builds confidence and new capabilities for the individual, but it also drives stronger performance and long-term retention for the company. Jordan’s story is a clear example of how investing in employee development creates benefits for everyone involved:

Since starting work in March of 2024 through KFI Staffing, Jordan has made a lasting impact. From the very beginning, he was supported by the KFI Staffing team during onboarding, which helped ease his nerves and gave him the confidence to start strong.

Throughout his time at work, Jordan has rotated through different areas, gaining valuable hands-on experience and continuously expanding his skill set. Recognizing his potential, the company enrolled him in their welding program to help him advance his craft. With the guidance of his supervisors and team leads, Jordan has continued to grow his technical expertise and confidence on the job.

Now recognized as one of the top 10% producers at the company, Jordan remains deeply grateful for the opportunity. His dedication, positive attitude, and commitment to learning are a testament to his success and his drive to keep building his career for years to come.

How to Get Started: A Talent Framework for Manufacturers

Total Talent Development (TTD) brings together workforce diversification, mentorship, and apprenticeships into one strategy. Here’s how manufacturers can apply it:

- Segment roles for entry-level hires who can grow into skilled positions.

- Map career paths with clear steps and skills.

- Pair mentors with new hires to accelerate learning.

- Build apprenticeships with compliant, cost-shared programs.

- Engage partners – staffing agencies, schools, and workforce boards.

- Promote your EVP – showcase your upskilling culture in hiring and outreach.

Why It Matters

Skilled workers don’t just appear ready-made. They must be grown – intentionally, equitably, and efficiently. A diversified, multi-channel, upskilled workforce isn’t just a hiring strategy – it’s an economic strategy. Kallie from MATC shared a moment that illustrates the power of early exposure:

“We had a student who initially didn’t want to attend Mini Manufacturing because he planned to pursue pre-med and didn’t think manufacturing would interest him. After the event, he had a deeper understanding of how many different pathways the industry offers.”

Stories like this show how hands-on experiences can shift perceptions and spark interest – even in students who hadn’t considered manufacturing as a career path. Even if students decide not to pursue a career in manufacturing, it helps them gain a deeper understanding of the importance of manufacturing.

Building the Workforce of Tomorrow

Upskilling isn’t just about keeping pace with the labor market – it’s about shaping the future of manufacturing. Companies that commit to developing their frontline workforce don’t just gain more productive employees; they foster loyalty, resilience, and a reputation as an employer of choice. By viewing talent as an asset to grow rather than a cost to manage, manufacturers create sustainable pipelines that power both immediate operations and long-term growth. That’s where strategic partnerships come in.

At KFI Staffing, we partner with manufacturers to build scalable workforce solutions that go beyond filling seats. We help companies develop entry-level teams that want to upskill into the skilled workforce they need. Together, we don’t just fill jobs – we build long-term talent pipelines and redefine what manufacturing talent looks like.

Citations:

- National Association of Manufacturers (NAM)

- Statistic: 2.1 million manufacturing jobs could go unfilled by 2030

- Website: https://nam.org

- U.S. Bureau of Labor Statistics (BLS)

- Statistic: Over 25% of manufacturing workers are 55 or older

- Website: https://bls.gov

- McKinsey & Company

- Insight: Third-party providers cut time-to-hire by over 30%

- Website: https://mckinsey.com

- National Skills Coalition

- Insight: Two-thirds of small and mid-sized manufacturers see schools as essential

- Website: https://nationalskillscoalition.org

- World Economic Forum (WEF)

- Statistic: Companies that invest in upskilling are 20% more productive and 27% more engaged

- Website: https://weforum.org

- U.S. Department of Labor (DOL)

- Statistic: 94% of apprentices stay employed after completion

- Website: https://dol.gov

- Aerospace Industries Association (AIA)

- Case Study: One aerospace manufacturer cut training time by 34% and improved retention by 22% through structured mentoring

- Website: https://aia-aerospace.org

- U.S. Department of Labor (DOL)

- Statistic: 94% of apprentices stay employed after completion, earning an average starting wage of $77,000 in advanced manufacturing

- Website: https://blog.dol.gov/2022/09/14/transitioning-from-active-duty-consider-becoming-an-apprenticehttps://aia-aerospace.org